High Efficiency Hydraulic Oil Press Machine | Reliable Supplier

Our hydraulic oil press machines are carefully designed to efficiently extract oil from a wide range of seeds such as sesame seeds, walnut kernels, pine nuts and almonds. Manufactured with high quality materials and well crafted, these machines are ideal for small to medium sized oil production operations.

Features of Hydraulic Oil Press

1. High efficiency and energy saving: advanced hydraulic system ensures high oil extraction efficiency and reduces energy consumption by up to 50% compared to traditional methods.

2. Easy to Operate: User-friendly design with intuitive controls that are easy to understand and suitable for operators of all skill levels.

3. Durable: Made of high quality materials including imported high manganese steel for durability and long lasting stable performance.

4. Versatility: capable of handling a wide range of oilseeds to meet different production needs, providing flexible and diverse solutions.

Specifications of oil press:

| Model | Power | Capacity | Weight | Size |

| 8YZ-150 | 0.75kw | 17.5kg/h | 250kg | 400*500*850mm |

| 8YZ-180 | 1.5kw | 24kg/h | 500kg | 750*950*1130mm |

| 8YZ-230 | 1.5kw | 48kg/h | 810kg | 760*1050*1450mm |

| 8YZ-260 | 2.2kw | 66kg/h | 1246kg | 900*1100*1600mm |

| 8YZ-320 | 2.2kw | 90kg/h | 1750kg | 900*1250*1750mm |

Application of Hydraulic Oil Press Machine

YZ series hydraulic oil press machine is widely used for processing all kinds of oil-rich seeds and nuts, such as sesame, walnut kernels, pine nuts, almonds, hazelnuts, flaxseeds, peanuts, rapeseeds and so on. It can extract oil efficiently while retaining the natural flavor and nutrients, ensuring high yield and quality products.

Customer reviews:

“The YZ-180 hydraulic oil press has significantly improved our sesame oil production efficiency. Its user-friendly design and high extraction rate exceeded our expectations.”

“The oil press and roaster are of excellent quality and the oil Yield is really good. Am very grateful for such good products and customer services.”

“The order was done in good time and it was delivered on the exact date.“

Maintenance Guide for Hydraulic Oil Press Machine:

- Electrical Requirements: please ensure that the machine is properly connected to the appropriate power source according to operational requirements.

- Grounding: Please implement proper grounding measures to ensure safe operation.

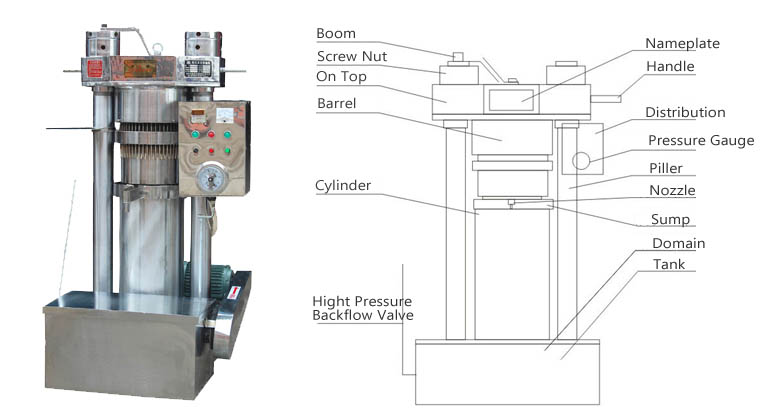

- Pressure Monitoring: Please check the accuracy of the pressure gauge periodically. Do not operate the machine if the pressure gauge is faulty or displays incorrectly.

- Routine Maintenance: After one month of operation, please filter the hydraulic oil and clean the tank. After that, it is recommended to change the hydraulic oil annually to maintain optimal performance.

For more information, to request a quote or to arrange a demonstration, please contact our sales team. Increase your oil production capacity with the reliable and efficient YZ series hydraulic oil press.