The development and application of cold oil press machine

The development of cold oil press machine

The development of cold oil press machines has been a significant milestone in the oil extraction industry. Although screw oil presses have been used for over a century, they have some limitations, especially when it comes to extracting volatile oils. To prevent the loss of nutrient substances in oil plants, low-temperature pressing technology, also known as cold pressing, is used. This process involves processing the material in a cold oil press machine directly, without flaking or cooking.

The absence of flaking and cooking processes in cold pressing means that the destruction of oil cells is incomplete, and the lipid and protein in the cells combine closely. Additionally, protein denaturation during cold pressing is minimal, resulting in high oil viscosity and poor liquidity. As a result, traditional screw oil presses and screw pre-press machines cannot establish suitable pressure or effective oil paths to meet the technological requirements.

To address this challenge, oil technology experts worldwide are working on developing an efficient new type of screw oil press. The cold oil press machine emerged as a solution to these challenges. Crude oil extracted using a cold oil press machine has a light color, with small protein denaturation of cake and low energy consumption. It is suitable for producing volatile special oils.

Leading international screw oil press machine manufacturing factories, such as Anderson International Co., Ltd. and French Oil Equipment Company in the United States, German Krupp Company, and Ross Downs Company in Britain, have been at the forefront of developing these machines. The capacity of screw oil presses produced by these manufacturers can reach up to 200t/d, with residual oil rates of dry cake below 3%. The capacity of pre-press machines can reach up to 460t/d, with residual oil rates of pre-pressed cake below 12%.

In the early 1990s, Anderson Company of the United States successfully developed a new type of screw oil press that achieved an oil extraction rate of up to 93.6% for sunflower seed kernels in single pressing, with residual oil in the cake at 3.5%. The crude oil’s color was light, with less nonhydratable phospholipids, simplifying the subsequent oil refining process and reducing the energy consumption of oil extraction and nutrient loss in the oil.

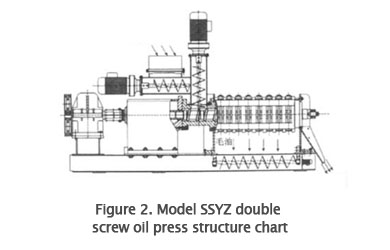

In the mid-1990s, Germany’s Cimbria-Sket Company and the Food Department of Essen Comprehensive University collaborated to research the theory of double-low rapeseed peeling and cold rolling processes for nearly ten years. They set up a pilot plant and developed the rapeseed peeling machine, peel and kernel separator, and cold oil press machine for rapeseed oil processing. Additionally, experts in the United States and Japan have been studying cold pressing using double screw oil press machines and achieved some results.

Since the late 1990s, our country has also begun to work on the research of cold oil press machine. The original purpose was to solve the problem of low temperature pressing after peeling of double-low rapeseed. Hubei province is located in the main rapeseed producing area of our country, it is also the first province to promote the double-low rapeseed. Thus, the research work of rapeseed peeling, cold pressing process and critical equipment have been in the national leading level. Wuhan University of Technology, Wuhan food and agriculture machinery manufacturing co., LTD. have developed the study earlier and obtained certain achievement. Below is a brief introduction to the new technology of cold oil press machine.

Rapeseed kernel after peeling would be sent into the pressing chamber of cold oil press machine under low temperature without flaking or cooking. Oil is extracted through screw extrusion, shear and moves forward and the cake would be discharged from the discharge outlet of pressing chamber so as to complete the working process of cold pressing. The whole process of cold pressing is kept at a lower temperature, and the material feeding temperature is between room temperature to 65 degrees below, and the temperature of cake discharging is not exceeding 70 degrees.

Equipment structure

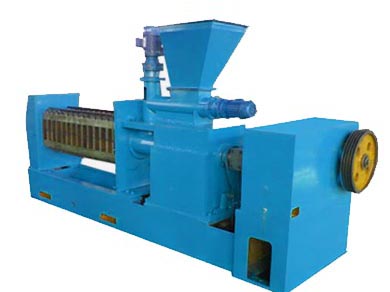

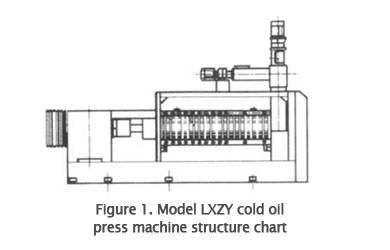

Cold oil press machine is mainly composed of mechanical drive system, worm shaft, pressing cage, feeding device, cake outlet device, slagging device, frame, electric control system and other parts. See figure 1.2.

Advancement of cold pressing

1, Oil extracted by cold pressing has light color and rich nutrient. Pure natural oil product can be obtained through precipitating and filtering. Decoloration and degumming are not needed, which saves the refining cost and reduces the refining consumption.

2, The protein damage of cold pressed cake is small, which is beneficial to the full use of oil protein.

3, Low pressing temperature (10 to 65 degrees), saving steam and reducing energy consumption.

4, The oil plant would not contact with any solvent, acid, alkali, bleaching clay or chemical additives during pressing. The nutrition and microelement loss of oil and cake are small. The protein content of cake is high.

Application of cold oil press machine

Oil temperature of cold oil press machine is low with high oil extraction rate, low oil residue, light color, good quality and rich nutrition. Therefore, besides being used in rapeseed peeling, new technology of cold pressing can also be widely applied to other oil plants through appropriate adjustment of the technical parameters, especially the organic plant and high-value crops, such as peanut, soybean, olive, walnut meat, corn germ, rice bran, tea seed, safflower seed, Chinese prickly ash seed, grape seed, flax seed, etc.

The development prospect and process flow of cold pressing double-screw oil press

With the promotion of healthy diet today and enhancement of health care consciousness, more and more consumers are pursuing the natural food processing effect that the health care function of all kinds of low temperature cold pressed oil is gradually well known. Cold pressing process can meet the needs of “green” consumption.

Because cold pressing adopts complete physical mechanical way of oil extraction that avoids the contact of cooking oil with organic solvent, acid, alkali, activated clay and high temperature in the current commonly used oil extraction. The cooking oil obtained can meet the requirement to eat only after filtering or drying, which ensures the nutrient retention of cold pressed oil and avoid the contact contamination.

Cold pressed oil is not only edible, it is also widely used in health care, cosmetic, medicine, chemical industry and many other fields. Because it is pressed by special oil plants, there is large difference between the price of raw material and product oil, thus it is very profitable. Cold pressed oil gradually become a favorite of the market.

Cold pressing is the physical method of oil extraction. Pressure in increased without heating up, thus it has no effect on the substance in oil. In addition to the common characteristics of general oil extraction process, it can also improve the oil quality, avoid the generation of harmful materials like trans-fatty acids or high quality polymer in high temperature processing and retains the active substances in the oil.

In the cold pressing of tea seed oil, cold pressed oil can avoid harmful substances such as acid, alkali and heavy metal in residual oil caused by adding chemical additives in the process of refining and shorten the process. A third of the production cost can be saved, the project cost of investment is reduced and the market competitiveness of products is enhanced. In addition, the nutritional value of protein in tea seed cake is improved after pressing, dietary fiber and other nutrients are not denatured and the active material can be kept that ensures the development and utilization value of cake. Therefore, this technique is suitable for the production and processing of high quality oil and macromolecular nutrients of oil crops.

Features of double screw cold oil press machine:

1, The double screw cold oil press machine adopts smooth chamber meshing screw pair technology with powerful propulsion and large pressure in the chamber. Single pressing, 93% of oil extraction rate and low residual oil rate of dry cake.

2, Double screw axis of special design with high theory compression ratio. Oil plants in the pressing chamber of cold oil press machine are compressed and expand five times to achieve the combination of thick and thin layer of material.

3, The easy wear parts are manufactured by carbonized steel and treated with strict heat treatment with high strength, toughness, low temperature impact toughness, abrasion resistance and long service life.

4, Cold pressing technology of double screw cold oil press machine cancels the crushing, softening, flaking and cooking process of hot pressing with less equipment, no environmental pollution, low power consumption and low production cost.

5, The unique cake outlet mechanism is used to support the screw shaft. The cake thickness can be adjusted in time when working.

6, The pressing cage is split in the vertical plane and supported by the hinge in both ends. Therefore, it is easy to remove the slag on the pressing cage with smooth oil extraction and convenient maintenance.

7, Cold pressing can fully retain the natural biological activity in vegetable oil, such as unsaturated fatty acids, vitamins, proteases, lecithin and trace elements. The vegetable oil extracted preserves the natural color, smell and flavor.

8, Strip pressed cake of cold pressing (oil dregs) is high-value food that can be used as animal feed, fertilizer, fuel and protein extraction.

9, Cold oil press machine is suitable for the cold pressing of special oil in various fields of food industry, pharmaceutical industry, cosmetics industry and energy industry.

Traditional hot pressing technology:

Oil plants – cleaning – shell kernel separation – drying and cooling – crushing and peeling – flaking – cooking – high temperature pressing – precipitation and filtration – refining – refined oil.

Cold pressing technology:

Oil plants – cleaning – shell kernel separation – conditioning – cold pressing – refining – cold pressed oil.

The utilization of cold pressing technology has revolutionized the conventional hot pressing and solvent extraction process. This advancement has streamlined the operation unit, enabling the simultaneous production of high-quality oil and low denatured cake. Moreover, it has enhanced the value of oil cake, making it more versatile and useful with a high additional application. Overall, the application of cold pressing technology has significantly improved the oil extraction process, making it more efficient and productive.