Palm oil processing technology and main equipment introduction

alm oil, as a relatively inexpensive edible oil variety with the highest production and consumption, shows a wide range of application prospects in many fields such as food, cosmetics and medicine. This kind of oil originates from the fruit of palm tree, and its oil content is as high as 45~50%, which is an important raw material for oil extraction. Palm fruit and kernel can produce palm oil and palm kernel oil respectively.

The processing of palm oil mainly includes the pretreatment of palm fruits, pressing, refining and other key stages. These stages ensure high quality and efficient production of palm oil through a series of advanced equipment and processes.

Palm Fruit Pretreatment

Pre-treatment is the key step in the preliminary treatment of palm fruits, which mainly includes washing, killing and de-fruiting.

- Cleaning: High-efficiency cleaning equipment is used to thoroughly remove the sand and impurities on the surface of the picked palm fruits, laying a good foundation for subsequent processing.

- Fermentation: Fresh palm fruits are sent into pressurized steam fermentation tanks, destroying the lipase enzyme in the pulp through high-temperature steaming and preventing the free fatty acid content in the oil from rising. At the same time, the high temperatures also loosen the fruits, making it easier to remove the fruits. The fermentation tanks used in this process have a highly efficient steam heating and control system to ensure the effectiveness of the fermentation process.

- Fruit removal: After the fermentation treatment, the palm fruit bunches are fed into the fruit removal machine, which separates the palm fruits from the bunches through vibration, wrestling, sieving and other mechanical effects. The fruits go to the pressing section, while the empty bunches are recycled as fertilizer or fuel. The de-fruiting machine adopts advanced vibration and screening technology to ensure the separation effect.

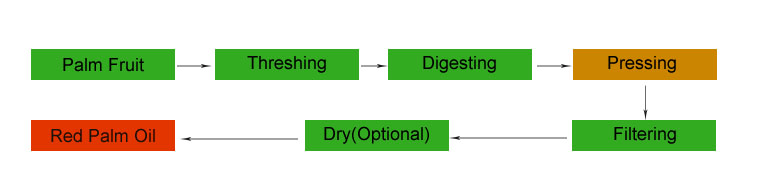

Palm Fruit Pressing Section

Crushing is the core of the oil extraction process from the palm fruit.

- Crushing: The palm fruit is crushed into a paste by the agitation and squeezing action of the crusher. This step helps to increase the efficiency of the pressing process so that more oil can be extracted. The crusher uses high speed rotating blades and strong squeezing force to ensure the crushing effect.

- Pressing: The mashed palm fruits are fed into the press oil press to get the palm oil through the pressing action. The oil press adopts advanced screw pressing technology to squeeze the oil out of the fruits through constant squeezing and friction. During the pressing process, the oil residue and other impurities mixed in the palm oil are separated and filtered by vibrating separating screen to ensure the purity of the oil.

Palm oil refining section

Refining is a key step for further processing of palm oil obtained from pressing, aiming at removing impurities such as free fatty acids, natural coloring and odor, and improving the quality and stability of the oil.

- Palm oil refining equipment: The refining plant is equipped with advanced refining equipment, including deacidification tower, decolorization tower and deodorization tower. These equipments deeply treat the palm oil through chemical and physical methods to remove the impurities and off-flavors, so as to make it reach a higher quality standard.

- Refining process: firstly, free fatty acids in the oil are removed by deacidification tower; secondly, natural pigments are removed by decolorization tower; finally, odor and volatile substances are removed by deodorization tower. After this series of treatment, the palm oil is not only of purer and more stable quality, but also has better taste and flavor.

Palm kernel oil extraction

In the process of palm fruit pressing, the palm kernel and fiber mixture can be further processed to extract palm kernel oil. High quality palm kernel oil can be extracted from the kernels by crushing, pressing and refining. This step not only increases the utilization of the palm kernel, but also provides the market with a more diversified range of oils and fats.