How to deal with the leakage of the oil press

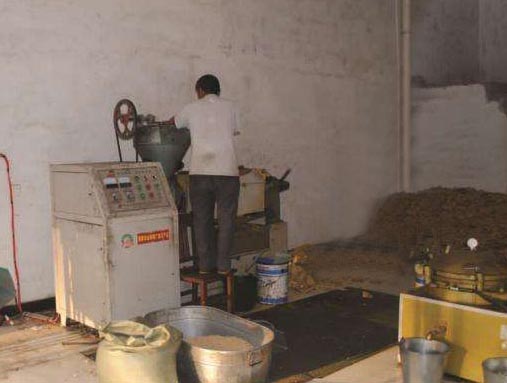

Oil press leakage is a common issue that arises due to prolonged usage of the machine. The friction force between the bearings and the filings from the friction lead to the leakage. However, there are ways to deal with this problem effectively.

Dealing with Oil Press Leakage

Firstly, it is important to clean the fillings. This can be done by shutting down the machine and carefully removing the accumulated filings. If the situation is serious, adding an oil proof pad on the machine can help prevent further leakage. In extreme cases, a new gearbox may need to be considered for replacement.

It is crucial to handle all these tasks with utmost care and attention. When oil leakage occurs in the oil press equipment, it must be shut down immediately to solve the problem. Continuing to work with a leaking machine can cause further damage and may lead to expensive repairs.

Regular maintenance and inspection of the oil press machine is essential to prevent such issues from occurring. Advanced maintenance is more important than repairing after the damage has been done. Therefore, it is crucial to keep a regular check on the machine’s condition and address any potential problems as soon as possible.

Dealing with oil press leakage requires careful attention and maintenance. By following these guidelines, you can ensure that your oil press machine operates smoothly and efficiently, without any leaks or damages. If you have any requirements for an oil press machine, please feel free to contact our sales team for assistance. With rich production experience and reliable production quality, we are devoted to manufacturing the best oil press machines for our customers.