Soybean quality change during storage and control measures

The importance of soybean storage quality control

Soybeans are a valuable crop widely used in various industries, from food production to biofuel manufacturing. However, the quality of soybeans can be compromised during storage, leading to significant economic losses and reduced product value. It is essential to implement effective quality control measures to maintain the integrity and usefulness of stored soybeans.

1. Soybean storage quality change

During the storage of soybeans, a series of physical and physiological changes can occur. These changes may result from the natural movements within the soybeans or external environmental influences. Some of the most significant changes affect the oil quality of the soybeans, ultimately rendering them unsuitable for use. Condensation, fever (elevated temperature), and mildew are common culprits that can lead to changes in oil quality and spoilage of soybeans. Therefore, it is crucial to implement effective quality control measures to prevent these issues.

2. Soybean Storage Quality Control Measures

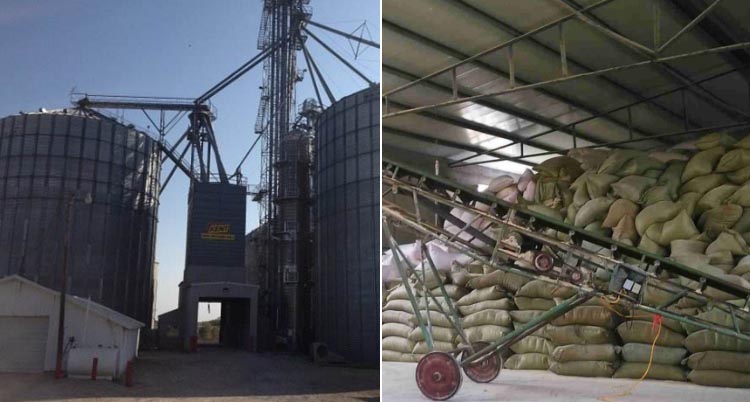

To ensure the quality of soybeans during storage, several measures need to be implemented. Conventional storage methods, such as using appropriate containers and maintaining suitable environmental conditions, play a crucial role. Additionally, impurity removal is of utmost importance. The presence of foreign materials, such as dirt, stones, or other crops, can accelerate the deterioration of soybeans and contaminate the oil. Thoroughly drying the soybeans is another key aspect of storage quality control. Proper drying reduces moisture content and prevents the growth of mold and bacteria, which can lead to spoilage.

Maintaining a suitable temperature is essential for soybean storage. Temperature influences the rate of chemical reactions within the soybeans, including oxidation and hydrolysis, which can affect oil quality. Ventilation and heat dissipation are critical in controlling temperature and preventing heat buildup, especially in large storage facilities. Adequate airflow ensures uniform temperatures and reduces the risk of hot spots, which can accelerate spoilage.

In addition to storage quality control, soybean processing methods also play a significant role in preserving the value of soybeans. Heat treatment combined with crushing is considered the most effective processing method for soybeans. This combination helps to extract oil efficiently while preserving the nutritional value of the beans. Extrusion technology, a cooking process that uses heat and pressure, is particularly suitable for soybean processing. It is energy-efficient and environmentally friendly, making it a preferred method for producing soybean by-products, such as soybean protein. Soybean extruders are essential equipment in oil mill plants, rice mills, soybean protein factories, and feed mills, enabling the production of expanded feeds and various soybean-based products.

Soybean Processing Methods

There are various methods for the processing of soybeans. The most effective soya processing method consists of a combination of heat treatment and crushing. Soybeans are low-oil crops and generally have a soybean oil content in the range of 1% -20%. Extrusion technology, as a cooking process, is particularly suitable for the beneficiation of by-products as it is energy efficient, environmentally friendly. Soybean extruder is the main technological equipment for soybean extruding and also can be used to manufacture different expanded feeds in oil mill plants, rice mills, soybean protein factories and feed mills. This method removes the anti-nutritional factor and makes the oil more accessible. In comparison, Soybean oil is regarded to be one among the several Vegetable oils.

By prioritizing quality control measures, the soybean industry can continue to meet the diverse needs of various sectors and ensure the satisfaction of consumers who rely on soybean products.